Adding a mA-meter to your machine is one of the most important modifications you can do on this machine.

The mA-meter will read the power trough your laser tube allowing you to set the power to a safe value to prevent the laser tube from over powering and thus saving the life span of the laser tube.

Read more here about the most common reasons why your laser tube dies.

Tools needed

– Wire stripper, cutter and crimp tool.

– Pliers or small wrench for nuts on the meter

– Drill bit and jigsaw to cut the hole in your panel.

Parts needed

– DC mA-meter, 0-30mA – you can get one trough Aliexpress here

– Wire, 1,5 to 2,5mm2

– Wire crimps (ring type)

How to do it

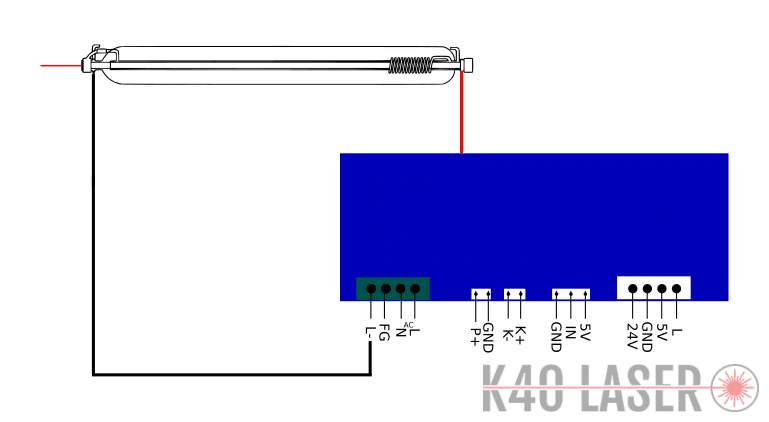

This is how the power wire from your power supply is routed on your machine without a mA-meter.

The negative cable coming from the left part of your tube (standing in front of the machine) and is connected to the L- on the power supply.

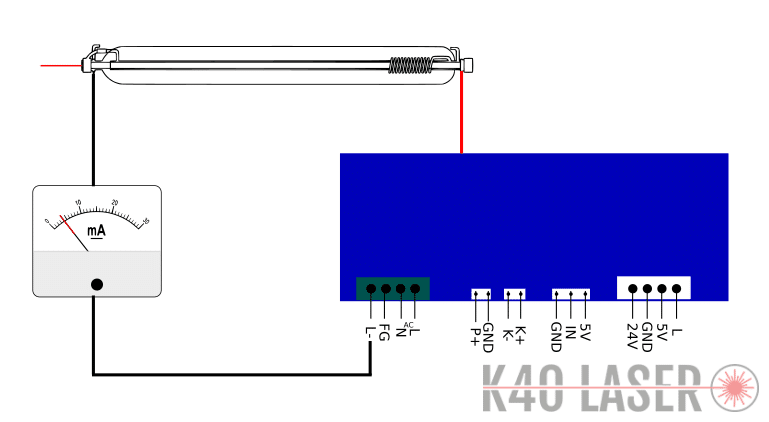

This is what we want to achieve

The negative wire comes from the tube to the input on the meter, and output from the meter going back to the L- on the power supply.

The easiest way to do this is to mark where you want the meter in your lid, take measurement of the size of hole needed (different for all meters) and drill/cut the hole, or make a external holder for the mA-meter on your lid.

The important steps

Before doing anything, remove all power cords and let the machine sit at least 30min before even thinking about touching something close to the power supply.

Step 1: Remove the L- wire from the power supply and route it up in the lid where your mA-meter will be located. Cut the wire so you have enough to crimp a connector on it without putting too much tension on the wire.

Step 2: Crimp a ring crimp connector on the wire, and attach it to the + marked input on the back of the mA-meter. Make sure to tighten the nut, add a dab of hot glue/super glue to prevent it from vibrating loose. Caution! If this wires comes loose it may create sparks, arcing or even fire due to the increased resistance if the connector isnt properly fastened, so take care to make sure both are properly crimped and fastened!

Step 3: Now check if the piece of wire you cut off earlier is enough from the mA-meter down back to the L- on the power supply. If not, cut a new wire with the length you need.

Add a crimp connector on the end and fasten it to the mA-meter.

Step 4: Install the wire coming from the mA-meter back on the L- pin on the power supply.

Step 5: Please, go over all your connections once more. Make sure the crimps are good and everything is fastened properly. Also check that the terminals on the mA-meter is well insulated if you have the meter above the lid. This is no joke, touching this will kill a grown man straight up!.

I suggest you add some electric tape on top of the crimp connectors afterwards, or seal them in hot glue to make sure nothing can touch them in your machine and causing a short.

You are now done!

Getting full scale deflection and yes its in the -ve side so faulty meter

But tips for others – to remove hot melt glue rather than risk heat on delicate components try a little isopropyl alcohol and the glue cones off.

First attempt at cutting the case I covered the psu with bags but a tiny shard of metal had found its way through and when I powered on – bang and had to buy a new psu

Be extra careful guys and if in doubt – dont

Updated to a 50mA ammeter, and it is pegged all the way to right after I fired a test shot. Does that mean the power supply is bad or try a different ammeter?

Cofirm the connection first. You need the mA-meter between the negative side and the PSU.

If you put it on the positive side, you will get 200mA instead of 20. (efficiency of the tube is roughly 10%)

If you are on the negative side (output side, left) its a bad meter. A stock K40 cannot deliver 50+mA on the ground side.

Or, if its actually a 5mA meter. But most probably a bad one.

I connected the black negative wire from the laser to the ma-meter neg post then from PSU to the plus post on the ma-meter.

Most probably a bad meter, they should not behave like that.

If the machine works as normal, the mA-meter is bad.

I attempted to do this to my k40 and the meter needle doesn’t move at all

Broken meter or wrong connections.

Hello and thank you for this awesome tweak!

I would like to implement it but for some reason (probably to prevent me from implementing it) all the connectors in my K40 are stuck in hot glue…

I have identified the blue wire at the end of the the tube. Would it be ok if I cut it in the middle and “insert” the meter along the line, without having to disconnect it from the board?

Also, and more importantly, could it be ok to use wire connectors (as in the picture) to make the wire longer, if the blue wire turn out to be a little short to reach my meter?

Yes you can cut it, but its better to remove it from the PSU and put that piece on the meter, and put a new wire between the PSU and the meter.

Length does not matter much, but try to avoid splicing or crimping the wire with extensions.

A little bit of heat from a lighter will make it easy to remove the hot glue on the connector on the PSU. But do this with the machine disconnected from power.

Thanks, you made me think that I could use my soldering iron to get the hot glue to melt. It seems like I would risk making less damage since I could apply the heat more precisely. I also have the feeling that it would be best to do this with a very low heat setting in order to avoid damaging the soldering on the board.

Hi All

Great guide thank you

I cut the wire from the Anode of my K40 laser (Front end) and put my amp-meter in series. The amp meter is 0-30mA. but when firing the laser, the amp meter maxes out already at a setting of 5%. Am I missing something, or is my Amp-meter faulty?

Anode as in red wire on right side of the machine when standing in front of it? Stop right away if you did this you can start a fire!

The input is 10x at least, you are feeding 200-300mA through the meter.

The efficiency of the laser tube is 10%-ish so whats coming out of the cathode (negative) wire is 0-25mA roughly.

No worries though, i have done it too when not thinking just move the meter and you are all fine 🙂

The mA-meter sits between left side (negative) cable and the FG/L- or ground on the PSU.

Make sure to check my illustration above and double check so the mA-meter is on the negative side of the laser tube. If it is, it sounds like its broken, or you have other power issues.

No not on the red wire :-), on the Black wire that is crimped with a blue that goes to the L- on the power supply. I tested with a known 20mA current I also maxed out, so I guess it’s broken

Perfect, then its broken as you tested. If you can´t find one locally, i can drop one off on Postnord from Sweden tomorrow. I got some that was used for photos so i can send you one. Send a email if you want one to hp@k40.se

Hi again, I got the new one today, installed it, and it works as expected. But thank you 🙂

A followup, what is the Max mA I can trow at it (standart 40W K40), and what is the max water temp before I need to stop it for cooldown?

I always keep my machines 16-18mA max. There is a few suggestions out there about max power but i would not go past 16mA with room temp coolant.

If you have a active cooler with temps down to 15-16C you can touch 18-20 for shorter periods.

This rule has kept my tubes alive for 2-3 years without issues before they need to be changed.

High coolant temps lower the efficiency of the regeneration of the gasses (so do high output power if not cooled) and will wear out the tube quicker.

Bigger tank, added frozen bottles of water helps a bit. I use wine brewing buckets for my coolant, 25L ones.

I try to keep my water around 15C. But for shorter work you can run it at 20-22c if its just a 10-min-ish work.

Above 25C is not recommended to run it at all, in my opinion.

Great thank you. Right now I have 10L of water at room temp, so I gues thats just small runs for me 🙂

Can you advise of a link on Amazon or Ebay for what type of wire to use? When I search Wire, 1,5 to 2,5mm2 im not coming up with anything.

Try with AWG12 and up to 14, its 1.5 to 2mm

Sorry if this question has been answered elsewhere, but if you upgrade to a 50w do you also need upgrade to a 50w power supply?

No. You will be limited to 35-40w output if you keep the stock PSU though. It works both ways, i use 80w PSU on a 40w tube in one of my machines, just keep a eye of the mA output.

Hey HP,

This site has proven invaluable to me in my learning process. Thank you.

Regarding your note where if I am to mount the mA Meter on the control panel cover I understand I should take care to insulate – could I ask you to elaborate a bit?

My question is should I be insulating the connections/terminals on the backside of the meter? Or should I insulate the mounting screws with like rubber washers?

Thank you! Also, would you be open to me sharing photos if I follow any of your guides? I don’t need anything in return, I’d just like to give back. I’m on your site every day reading and re-reading. Amazing work.

Thank you, glad the guides has helped you.

On the mA-meter, just make sure the nuts can´t move. Use nylon lock nuts or add some hot glue so they stay put when the machine vibrates. If they loosen up the resistance increases and it can cause a fire.

Insulate is most if you might touch the nuts or pins with other cables or connectors while the machine is running, you dont need to but it´s a good thing to do. I cover mine in hot glue after the nuts are tightened, and i use shrink tube as far up on the cables i can.

Feel free to send pictures to help@k40.se

HI

Your instructions are very clear. I thought i followed all and double checked the wiring all secured. However when I turned on the k40 the digital display keeps fluctuation from 0 through to 90 over and over without stopping.

i tried a laser test and the analog meter went to 20.

what can i do to correct this.

Do you have the digital version of the machine and that display is doing something stupid?

If this happened when installing the mA-meter – remove it again and go back to how it was. If the issue is still there the digital controller has given up, not related to the mA-meter it just happened at the same time.

Test with removing the mA-meter first to verify whats going on.

Send a email to help@k40.se if you need more detailed things to check. (this help is free)

Great guide. Works fine! Thanks a lot!

Do you a shunt with your amp meter? Or don’t you need one.

No need for it if you use the meter shown above, very common on Ebay, amazon and aliexpress.

The current is roughly 0 to 20-25mA so a shunt is not needed. The meter shown has a built in resistor for the 30mA max.

Hello is it possible to install 50ma miliamperometertok40 laser?

Thank you.

Yes, but the resolution will be very small as you should never go beyond 14-16mA on a K40, so it will be hard to tell what the output power really is.

Mus tit be an analog meter or can it have a digital readout?

I have tested several digital meters, but none of them has been quick enough to show correct values when engraving, the output fluctuates so quick the digital meter shows a lower value than it really is.

I have both digital and analog meter in one of my machines and for cutting or doing a single pulse its a good option with a digital, but i would not recommend setting the power level by looking at it when engraving as the LCD display wont update quick enough and you get a median value from the real value.

There is better higher quality digital meters out there though – but still, the quick changes in power when engraving will be hard to see on the LCD.

It looks like my ps has 5 wires running in and out of the back one main pos to the tube the ground for the tube comes straight from the wall power jack then there is a green block labled as follows FG:AC:AC:L- I thought I would hook the amp meters from the L negative to the ant meter then back to the El negative block this did nothing I also tried to put a passive magnet type milliamp reader are the negative lead from the power block to the main power and that did nothing. I don’t want to cut the wire coming from the power block that is going to the tube just to install a power meter any suggestions?

You need to put the meter between the power supply and the negative cable going to the laser tube, it doesn´t matter how you do it as long as its in between.

i have a K40 with digital readout that shows the useless % instead of ma. I want to do this mod, but what happens to the digital % readout once i switch to this. this is left out in the instructions. how do the ma meter and the digital interact with each other?

They dont interact, but you can still use the digital readout for quick power setting. Example if you cut 3mm arylic at 25% at the digital readout and the power output on the mA-meter is within safe levels (not over 15-16mA) you can use that as a guide to set the power easier.

Use the mA-meter as a safety check, so you never go above 15-16mA to spare the life of your laser tube. You can go 18-20mA for a short short run but it´s not advised to do so.

The mA-meter just reads the real power output of your tube – the digital panel sets it.

Your drawing shows the wire from the tube going to L- pin

On my machine, the wire from the tube goes to FG pin; The L- pin is connected to the ‘ground wire joint’

Are the L- pin and FG pin connected?

And when installing the meter, should I install the meter between the negative end of the tube and the L- pin?

I would suggest you are changing it to how it´s supposed to be connected. FG and L- are connected internally but they should not be connected like that.

Install the meter between negative cable from the tube and L-, then you know everything is up to code. Some PSU´s has a controller on the L- to measure some stuff – so its always best to go with the standard, even if the FG works technically.

My new K40 is wired like the guy above L-1 to ground block on back wall of power supply compartment and the tube iis wired to the FG terminal. So that being said am I actually wiring between the L-1 terminal and the FG terminal or are you saying to rewire the laser machine to your old specs? This K40 has the all digital display with buttons to adjust power no potiometer like originals. I just want to be sure what you are saying before I wire something wrong and blow up my machine.

Thank you for this web site it has given me a lot of good info as I am brand new to the Laser arena.

FG and L- are connected on the inside of the machine, its the common ground.

BUT, as these machines are grounded very poorly i tend to suggest always putting the laser tube on L- and FG to case metal in the back of the machine just to follow a similar suggestion to everyone – not because one is better than the other 🙂

If you follow the guide how to properly ground your machine, you can use FG or L- for the laser tube – it wont matter. See the article here: https://k40laser.se/diy-how-to/warning-for-new-machine-owners-grounding-issues/

I read the grounding guide, thank you again. I will remove the paint to make sure the case has a proper ground and I will swap the L-1 and FG wires before installing the ma meter per your advise.

I need to ask you another question concerning the wattage of my machine because from what I have seen on everything I am watching and reading I believe my laser is a 30 or 35 watt machine. The Laser tube is 635mm long not 700mm long and is 50mm dia. Am I correct in what I have told you? And as I am sure the seller will probably fight me on this so my next question is where do I find replacement 635mm laser tubes? I have looked on line for hours and found no one that carries them. But there is a removable plate on the end of the machine in the laser tube compartment I believe this is to allow for me to upgrade to a full 40watt 700mm x 50mm laser tube if so will my existing power supply work with the bigger tube?

In my opinion you should have been a Priest or some kind of clergy because I have read your site backwards and forwards including the questions and your answers and my friend you have the patience of Job and you are also a great instructor because your explanations can be understood by the novice or expert. I hope you can shed some light on my new questions so I can either kill myself or proceed. Thank you.

Correct, the ~635mm tubes are roughly 32-33 watts. I have measured 20+ of them. 700mm is more like 38-42w depending on age and vendor. I like YongLi or TongLi tubes, they last for ages and are very stable. My current 40w TongLi is 2 years old now and still outputs 36 watts.

The seller say they are 40w, you can create a output of them at 40w but you will kill the tube quickly – at 16mA which is the maximum power to these 635mm tubes they generate roughly 32 watts. If you put in 18 or 20mA they can spit out 40w but it´s not stable and the regeneration process kills off the gasses in a few weeks at those levels.

But, most cheaper (sub 300 USD) Co2 tubes are like this, if you buy a 50w you get 44-46w, and a 80w gives you 72-75w and so on 🙂

Keep the 32w tube you got with the machine, use if to learn the machine and when you are ready to make stuff to sale or similar – buy a better 40 or 50w tube (you can use the same PSU for a 50w, you wont get 50w out of it, but a more stable beam and quality on the engraving).

Ok Ma meter is hooked up. Question, will digital push button controld adjust the ma up and down? Question, I am the one with the 635mm tube, what ma would you recomment me to run on that so I dont burn out tube, you said 16ma above but isn’t that pushing it? I haven,t recieved my new submersible pump yet so is the one that comes with the laser unit a submersible pump that I can use for a few days? Air assist is hooked up. Also waiting for new inline exhaust fan so will use the one with machine to start. I just want to get lens cleaned and aligned and see if this thing works. Thanks again

The digital panel is controlling the mA, but never go beyond 60 on the digital one (on the 0-100 scale). Get a mA-meter (0-30mA) to have perfect control of your power settings.

16mA is the maximum i would use, and you probably never need it. 10-12mA and you are good for cutting, engraving even less, maybe 3-4-5mA depending on what you do and the speed you are running at. Just make sure the water keeps below 20c to save the life of the laser tube.

It´s a bit complicated, but the regeneration process of the gasses inside the tube slows down if the tube is hot – there is not a 1:1 ratio so the tube dies after a few years due to this effect. But with hot water, or over-powering the tube this regeneration process slows down even more and the tube dies quicker.

Hot coolant makes the tube consume a lot more than it regenerates to put it simple 🙂

Use the pump included, it works but no one knows for how long 🙂 A little flow sensor can save you a lot of money if the pump dies, a few bucks and it kills the PSU from firing the tube if the flow is low.

A few drops of dish soap in the water keeps the bubbles out – and make sure the return hose is below water surface to prevent more air in the water. Some likes to use the dripping sound as a flow indicator – don´t do that 🙂

This unit has a temp probe hot glued to the power supply, do you have do not exceed temp for that , I have looked but haven’t seen it any where, figure i have it might as well monitor that also. And how much anti freeze to how much distiller water? I will be using a 5 gallon bucket to start but will be shifting to a small ice chest as it will keep the water cooler longer and keep ice bottles longer I think.

No max-temp for the PSU, as cooled as possible is the key. I have a article how you can save it from over heating with tilting it to pull air from the outside, instead of circulating the hot air it creates. Search for “tilt your psu” on this site to find it.

Antifreeze should not be in the water at all, depending on brand it will make the water conductive and lower the power output and destroy the generation process and even create arcing inside the laser tube compartment.

Some types of RV-antifreeze works better as they do not have the conductivity issues, but i tend to stay away from recommending it at all due to differences in brands. Heat is always better than anti freeze additives if you keep the machine in a cold spot. Or empty the tube completely after use to prevent the laser tube from cracking from freezing.

Read more about coolant and additives here: https://k40laser.se/watercooling/watercooling-deep-dive/

This article has been closed a while, as i´m re-writing it. But i opened it again now so you can take a read. It´s not 100% as much has changed since i wrote this in 2016 but the bigger picture of cooling is still valid.

https://k40laser.se/watercooling/watercooling-different-coolants-for-your-laser/

Is the process any different when installing the meter on a k40 with digital controls?

It´s the same

Great Idea! Newbie question: But how do I control to not over power my tube? Do I need a potentiometer or a knob or something like that, to deal with the power shown on the mA-Meter?

Most lasers has a potentiometer or a digital panel controlling the power settings. If you don´t have one, you need one to set the maximum output to not over power the tube.

I have followed your instructions and installed the mA meter. It works fine. Good to see I have not been overpowering my laser!

Next mod. is smoke assist (I already have air assist).

Thank you for your very helpful and informative site.

Steve Tagg.

I intend to fit a milliampere meter as you suggest – it makes sense. I have ordered the meter from you and was wondering wondering about the type of cable to use if the cut off cable is not long enough. I presume it must be insulated to withstand more than 20kV?

Thanks for your very informative site.

Steve.

Negative lead does not have much voltage, it´s “consumed” by the tube. A 1.5mm2 cable is good enough. Your machine probably has one already in that size.

Great! Thanks for that.

Question, would it be beneficial at all to attach a ground wire to one of the mounting screws?

I am waiting for my meter to be delivered and I will be attaching it to the lid so all connections will be internal.

No, run a solid wire from output on the PSU to the mA-meter, and the other one to the tube. They are grounded inside the PSU but i think there is a sense on it, if you ground it somewhere else the PSu might stop firing the tube.

Have a question. Your drawing shows the wire from the tube going right to the PS. On my machine the wire from the tube goes to this tube/coil on the side of the machine then to the PS. Is this some kind or resistor?

Yes, some older types of PSU´s have a extra green cap mounted inside the machine, if it´s routed to this first, the meter should go between the tube and the cap/coil thing.

Followed instructions and didn’t die. Would recommend. Great tutorial

My ma meter didn’t have – marked on it. What would happen if its wired the wrong way round

Nothing happens on most of them, if you don´t get a reading swap the cables around.

Danke ,,, ganz tolle Anleitung !!!

Hat sofort funktioniert.

Wer sich an Ihre Dokumentationen und Regeln hält, macht nichts verkehrt und hat viel SPAAASSS mit seinem Laser.

Gruss aus Lübeck …. K.C.